Boron nitride (BN) is a synthetic ceramic material that occurs in two modifications. One is the hexagonal BN (α-BN) that shows a graphite-like layer structure. The other one is the dense cubic BN (β-BN) with a structure similar to that of diamond.

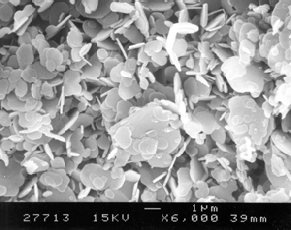

Fig. 1. SEM micrograph (secondary electron image) illustrating the plate-like particles of boron nitride powder.

Boron nitride was first prepared on a large-scale basis by Union Carbide and Carborundum in the 1950's. Today the following three general reactions are used for the synthesis of α-BN using boron oxide (or boric acid) and a nitrogen-containing compound:

B2O3 + 2NH3 → 2BN + 3H2O (T = 900°C)

B2O3 + CO(NH2)2 → 2BN + CO2 +2H2O (T > 1000°C)

B2O3 + 3CaB6 + 10N2 → 20BN +3CaO (T > 1500°C)

The resulting boron nitride contains 92-95% BN and 5-5 % B2O3. If desired the remaining B2O3 can be evaporated in a second step at temperatures >1500°C in order to achieve BN concentration >98%.

BN production figures are not listed separtely in statistical reports, however we estimate the 1999 production for the western world of about 300 to 350 metric tons. Production figures will be similar for 2000 with a slight increase possible. Also there is a BN production in the Commonwealth of Independent States (CIS) and China, no reliable production data are available.

Companies involved in the production of BN include Advanced Ceramic Corp. (formerly Union Carbide) and Carborundum Co. in the United States; Boride Ceramics & Composites (owned by Sintec Keramik GmbH & Co. KG, Germany) in the United Kingdom; Elektroschmelzwerk Kempten and H. C. Starck GmbH & Co. KG in Germany; and Denki Kagaku Kogyo, Kawasaki Steel Corp., Shin-Etsu Chemical Co. Ltd. and Showa Denko KK in Japan.

Prices for hexagonal boron nitride range from about ∼$75/kg to $120/kg for standard qualities depending on purity of BN and may reach prices up to $200-$400/kg for high purity and tailor-made grades. Although at present a large demand for boron nitride exists, there are no large price increases to be expected in the near future.

For ceramic applications the hexagonal modification is used because of it outstanding chemical, thermal and electrical properties. It finds application in the metallurgical field because of its good non-wetting behaviour against metallic melts. Further applications are high temperature solid lubricants because of its layer lattice and thermal conductor/electrical insulator in electronic applications. Large quantities of BN are used for the production of engineering ceramics like break rings for horizontal continuous steel casting and TiB2/BN composites used as evaporator boats for vacuum metallization. Other applications include those in the field of cosmetics, as catalysts and as a starting material for the production of cubic BN. Due to its extreme hardness second to diamond cubic β-BN is used as a hard material.

The very good non-wetting behaviour as well as the good high-temperature lubrication make boron nitride an ideal release and parting agent for the production of aluminium and magnesium castings as well as glass forming and superplastic forming of titanium sheets for aerospace applications. In these applications boron nitride is used as a dispersion in a carrier (water or alcohol) blended with refractory binders, that are applied like wall paints. Such coatings are produced by Advanced Ceramic Corp., Carborundum Co. and ZYP Coatings Inc. in the United States and by Elektroschmelzwerk Kempten and Büro für angewandte Mineralogie in Germany.

Stephan Rudolph, Büro für angewandte Mineralogie

from: American Ceramic Society Bulletin, 79 (2000) 6, p. 50

![]() Gesamte Veröffentlichung als pdf herunterladen.

Gesamte Veröffentlichung als pdf herunterladen.

© 2023 Büro für angewandte Mineralogie · Dr. Stephan Rudolph · D-47918 Tönisvorst

Vorstehende Angaben entsprechen den im Labor und Betrieb gemachten Erfahrungen. Sie können jedoch in Anbetracht der wechselnden Verhältnisse nur als Anhalt dienen und sind in diesem Sinne als unverbindlich anzusehen. Diese Produkte sind nur für den industriellen Bereich und vergleichbare Anwendungen (z. B. Forschung und Entwicklung) bestimmt. Die beim Umgang mit Chemikalien üblichen Vorsichtsmaßregeln sind zu berücksichtigen. Schutzrechte Dritter bitten wir zu beachten.

www.a-m.de